No compromises on Quality

As part of the Würth Industry Group, Thomas Warburton has access to the Würth range of Quality Products, Accredited Testing Laboratories, engineers, technicians and masters of their craft from around the globe.

Before any product is added to the Würth range

Products are subjected to several days of endurance testing in the Würth Group’s Test Laboratory, which is certified to DIN EN ISO/IEC 17025.

The central testing facility is supported by product testing operations in the USA, Europe and Asia. The combined knowledge of each centre contributes to ensuring quality across the board.

The following quality assurance tasks are conducted:

-

Initial sample testing

-

Incoming goods inspection

-

Complaint processing

-

New product testing

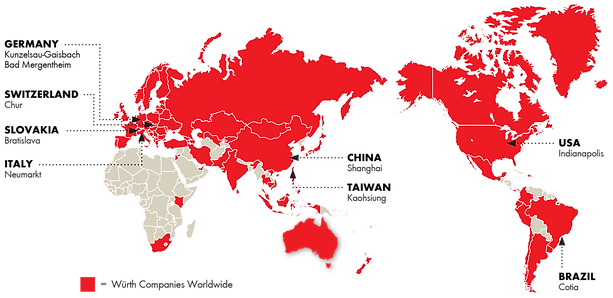

The map below displays the locations of the largest Accredited Testing Laboratories available to Thomas Warburton within the Würth Group.

Please note, not all locations can facilitate all test methods presented on this page.

A wide range of tests and measurements are carried out, including but not limited to:

-

For metals and plastic

-

Small-load

-

3D-coordinate measuring machine

-

Contour measuring device

-

Optical rotation measurement system

-

Measuring microscope

-

Surface-roughness measuring device

-

X-ray fluorescence spectroscope

-

Pulling test rig for dimensions up to M80

-

Torque test rigs

-

Tension testing machine

-

Impact test bending facility

Want to know more detail

about the above tests?